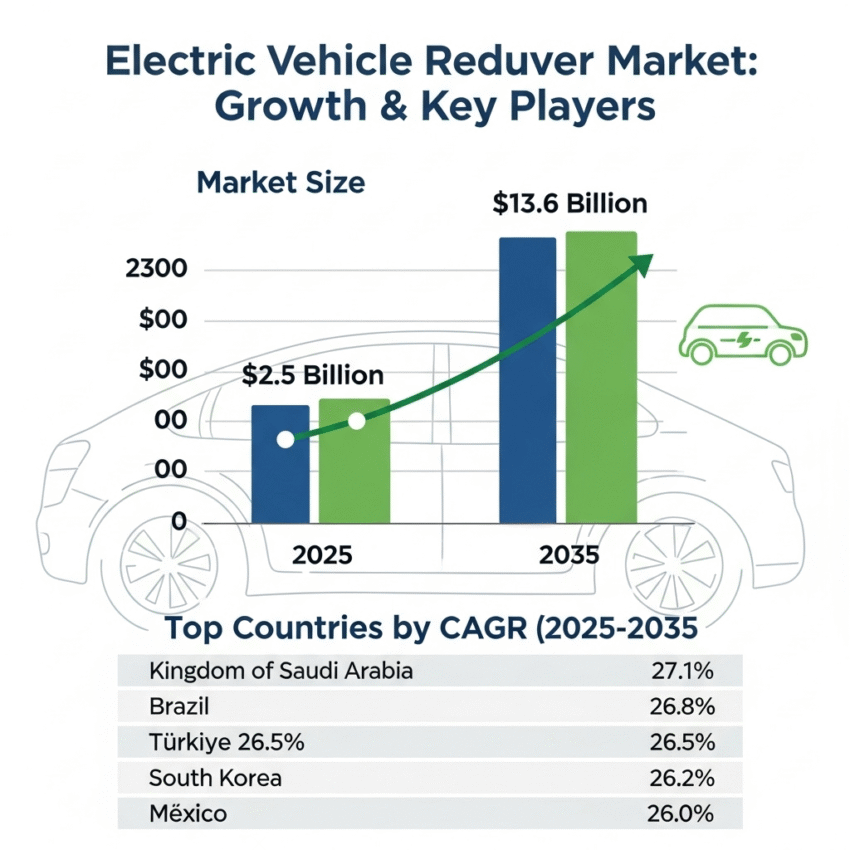

The electric vehicle (EV) revolution is already underway, and a key component quietly powering this transformation is the electric vehicle reducer. Often overlooked outside engineering circles, this compact gearbox is essential in translating motor power into wheel torque, enabling smooth acceleration, efficiency, and durability for EVs. Now, as global EV adoption accelerates, the market for reducers is projected to soar from USD 2.5 billion in 2025 to a remarkable USD 13.6 billion by 2035, expanding at a strong CAGR of 18.5%.

This growth is not just a story of numbers—it’s about how innovations in drivetrain design, materials, and manufacturing are shaping the cars of the future.

Why Reducers Matter in the EV Era

For many drivers, reducers are invisible, tucked inside the drivetrain. But their role is pivotal. They bridge the gap between high-speed electric motors and the wheels, ensuring efficient torque delivery while minimizing energy losses. Punch Powertrain, a leading supplier, recently highlighted that reducers account for nearly one-third of total drivetrain losses—a reminder of just how critical efficiency gains are.

According to Joris Bronckaers, Engineering Leader for EV at Punch, “What makes the difference between a good reducer and an exceptional one is the effort you put in it.” That effort increasingly revolves around modularity, noise reduction, and durability under extreme torque cycles—all vital for consumer-friendly EVs.

Market Momentum: What’s Driving the Surge?

Three primary forces are propelling the market forward:

- Soaring EV Adoption – With governments tightening emissions rules and consumers shifting toward sustainable mobility, demand for EVs—and therefore reducers—is climbing globally.

- Compact E-Drive Systems – Automakers need lighter, space-saving drivetrains. Reducers designed with coaxial or offset formats are enabling slimmer vehicle architectures without compromising power.

- Technological Breakthroughs – Innovations such as multi-speed reducers for smoother torque transitions, advanced cooling systems, and lightweight alloys are making reducers more efficient and robust.

Shifting Trends: From Single-Stage to Multi-Stage Systems

Currently, single-stage reducers dominate, making up about 64% of the market in 2025. Their popularity stems from simplicity, compact design, and cost-effectiveness. They’re especially common in compact and mid-sized battery electric vehicles (BEVs).

However, multi-stage reducers are gaining ground. Their ability to provide seamless torque and speed transitions—without clutches—makes them ideal for performance EVs and plug-in hybrids. Analysts expect this segment to eventually capture over two-thirds of global market share, fueled by consumer demand for smoother rides and longer battery life.

Spotlight on BEVs: The Largest Growth Segment

Battery electric vehicles (BEVs) are expected to lead reducer demand with a 68% share in 2025, growing at a CAGR of nearly 19% through 2035. As BEV adoption accelerates in regions like China, Europe, and North America, automakers are integrating reducers that prioritize quiet operation, weight reduction, and regenerative braking efficiency.

Global Growth Patterns: East Asia Leads, India Emerges

- China remains the powerhouse, accounting for nearly 45% of global EV sales. Its strong manufacturing base and consumer incentives ensure that reducer demand here will remain robust.

- United States is seeing a rapid shift thanks to federal tax credits, charging infrastructure investments, and the electrification of commercial fleets.

- India is emerging as a high-growth region, spurred by government-backed schemes like FAME and local investments in EV manufacturing.

- Other high-growth markets include Saudi Arabia (27.1% CAGR), Brazil (26.8%), and Turkey (26.5%).

Innovation in Motion: Lightweight, Modular, Smarter

The industry is undergoing a materials revolution. Traditional steel components are giving way to high-strength aluminum and lightweight composites, which reduce vehicle weight and extend battery range.

Cooling and lubrication systems are also being redesigned to minimize thermal losses—a critical factor for heavy-use vehicles like electric vans and trucks. Jabil, in its 2024 market briefing, noted that software-definable EV components are becoming standard, with digital twin simulations streamlining both design and supply chains.

Beyond Cars: The Future of Reducers

While cars dominate current demand, electric commercial vehicles (e-LCVs) and pickup trucks represent the next growth frontier. Ford’s expanded electrification roadmap—covering vans and trucks—highlights the need for compact, durable reducers capable of handling heavier loads.

Additionally, advances in charging infrastructure are creating ripple effects. As charging becomes faster and more accessible, range anxiety declines, encouraging wider EV adoption—and by extension, more demand for reducers.

Leading Companies in the Electric Vehicle Reducer Market

- Aichi Machine Industry

- BorgWarner Inc.

- GKN Automotive

- HOTA Industrial

- Magna International

- Robert Bosch GmbH

- SAGW (SAIC General Motors)

- Tsingshan Industry

- ZF Friedrichshafen AG

- Zhuzhou Gear

EV adoption accelerating worldwide, the electric vehicle reducer market is set to become a cornerstone of future mobility. Continuous innovation in lightweight materials, modular design, and efficiency will shape competitive advantage for automakers and suppliers alike.

Related Market Data: https://www.futuremarketinsights.com/reports/electric-vehicle-reducer-market